Technology & Innovation

Patent Solution

Aster always lays stress on the research and development of its own patents. We have the best knowledge and understanding on the toner cartridges patents. Our powerful team of IP engineers dedicating in patent research always makes sure our products are free of patent risks.

- In-house powerful team of IP engineers dedicating in patent research

- Close partnership with the well-known law firms

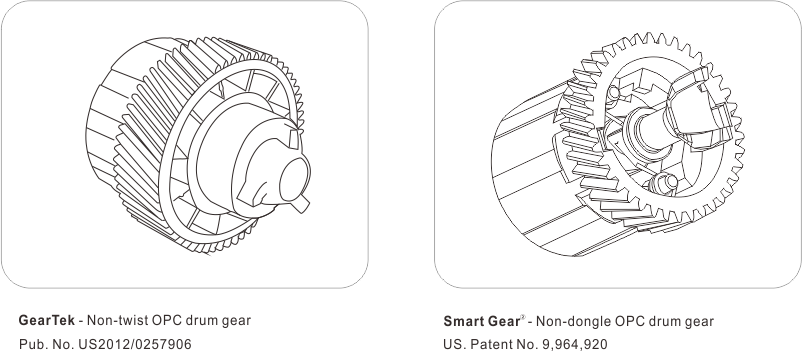

- Own key patents such as GearTek solution and Smart Gear solution

R & D

Aster has some of the industry’s most knowledgeable professionals who have the best knowledge and understanding on the toner cartridge technologies and are passionate about engineering innovation. From the very beginning of the establishment, Aster set out a long-term plan on yearly increasing investment into R&D. By doing so, Aster can always ensure its customers remain ahead of the competition.

- 360,000㎡ industrial park

- 70 professional engineers and specialists

- In-house plastic molding factory

Quality Control

Aster delivers cartridges that are produced according to the highest quality standards and meet or exceed OEM quality at highly competitive prices.

1. Inbound Raw Materials and Components Tests

We work with the top tier suppliers of raw materials and components to ensure the reliability and consistency of our product's quality. All incoming materials: drums, toner, blades, PCRs, magnetic rollers, etc. are verified against stringent standards before they reach the production floor.

2. Sort Empty Cartridges

All empty cartridges are sorted and graded. Only premium empty cartridges are used to ensure optimal quality.

3. Ultrasonic Welding

For new compatible cartridges, ultrasonic welding will be used to prevent leaks.

4. Filling Process

By using automated filling equipment, each cartridge is precisely filled to the exact specified weight. Toner hoppers are filled with premium toners, which are technically matched to the OPCs for optimal yields and printer performance.

5. Assembly

Every step of production is strictly inspected by the Quality Assurance Team. They check for spots i n the key production steps to conduct a 100% inspection.

6. 100% Post Testing

Every cartridge is tested at the end of assembly to capture and identify any assembly or component errors.

7. Retain Samples Testing

0.5% of the packaged cartridges will be randomly selected to perform life testing and extensive environmental testing.

8. Packaging Inspection

All cartridges receive a final inspection to ensure stringent quality standards. Cartridges are cleaned, polished, heat-sealed in a static resistant bag and boxed. A full set of instructions and warranty information is included.

9. Tracking System for All Products Sold

All Aster products are traceable. Each cartridge has a bar code contains its components; production date and production team information, etc. This information makes it easy to trace and analyze the production history of a returned cartridge in our ongoing effort to always provide the highest quality product.

10. Certifications

Green Policy

As a printer supplies manufacturer, we are more concerned about the environment and we are committed to reducing the waste and further to decreasing the damage to our precious environment. At Aster, we offer a closed loop environmentally recycling solution, by collecting and recycling empty cartridges which would normally end up in the landfills.

How it works

At Aster, all the collected spent OEM cartridges are sorted by our trained staff, dismantled and evaluated. If the cartridges are not suitable for remanufacturing, they will be recycled in an environmentally responsible way. If they can be remanufactured or reused, they go through the rebuilding, refilling and further testing processes and then are resold in the market if they meet our quality standards. This process is more beneficial for the environment than even the recycling carried out by the original manufacturers which involve a heat-based industrial process to separate the plastic and metal components which are then melted down to be reused in other products or simply broken into pellets before being discarded as waste and ending up in a landfill again.

In addition to recycling the used cartridges in an environmental friendly way, in our daily operations, we also try our best to reduce our impact on the environment, such as recycling the cardboard packaging, plastic cartridge bags and pallets.